Vein, pattern and colour matching of worktops

Matching vein & pattern in jointing pieces

Colour, pattern and vein matching with some colours of granite and quartz can be problematic due to the wide variation through each individual slab or from one slab to the next, even when they are from the same batch. It’s not always possible to match through these colours and patterns from one worktop to the next or from worktops to wall panels and upstands.

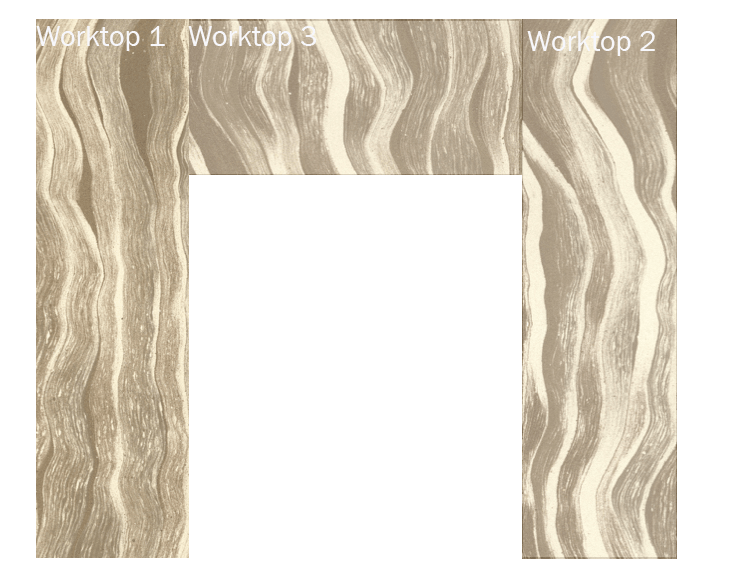

When a project is quoted, a certain number of slabs are allocated within that price. As an example, here we look at a small kitchen made of 3 pieces of Cambria Oakmoor quartz. This is a highly patterned material with a strong directional vein and so illustrates our example perfectly. You can see from the image on the right a full slab marked for fabrication, the 3 pieces needed will just about come off 1 full slab.

U-Shape kitchen layout

In this example the colour and vein matching work out well. Although the areas where joints will be are not fully matching, all the grain and flow of the materiel is going the same way. In this layout, one slab works perfectly to get the kitchen with all the pattern and vein matching very well.

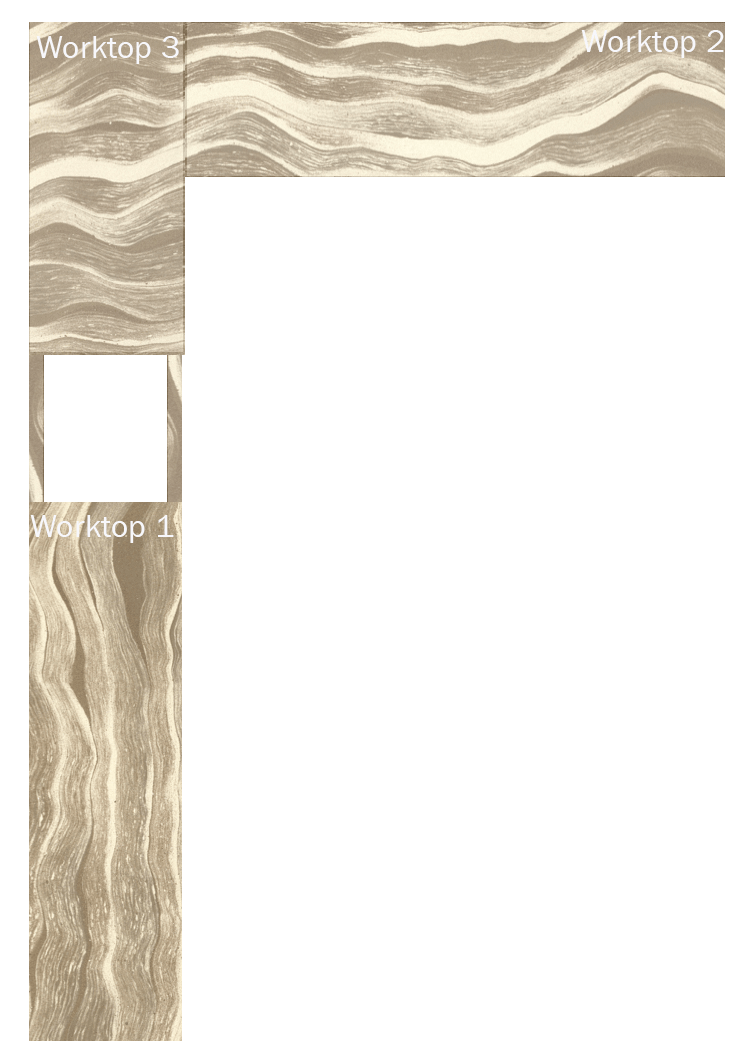

L-Shape kitchen layout

In our second example we are using the same pieces as example 1 but this time the layout is different. As you can see the vein and grain are not running the same way on all the pieces.

To get the grain and movement all flowing the same way, we would have to price an additional slab into the cost of the project. This can be a very expensive addition and the biggest part of the quotes total.

Sometimes it just isn’t possible to get all the grain running the same way no matter how many slabs you have. If for example you need 3 worktops at 3m long but to match the grain on one of these pieces needs to come off the end of a slab, it’s just not possible as most slabs are only a maximum of 2m high (max 1.6 meters in quartz)

Matching shade & pattern in jointing pieces

Its not only the heavily veined & striking material that can cause this issue. Some colours will change throughout the slab in patches of colour and markings such as Cambria “Berwyn” for example (see the image to the right)

Colours such as the Cambria Berwyn have lighter and darker areas so depending on how the slab is cut, you may have a worktop with a darker area that joins to a worktop that’s cut from a lighter area , causing an issue for some customers. If purchasing a colour like this you would have to be prepared for this as very often, even with the most careful cutting and our attempt to match, it may just not be possible.

Very light part of the slab with less marking

Much darker part of the slab with heavy markings

The image on the left shows a joint of worktops in Cambria Berwyn. As you can see the worktops and jointing area are not perfectly matched but are cut from the same slab.

The image on the right shows jointing of worktops in White mirror quartz . If you choose a plainer colour such as this, with small grain & repeating pattern, there is no issue with colour matching.

We endeavour to match joints in all material but as you can see from the examples above, its not always possible in every colour. If you are concerned by this please contact us for more information on the colour you have chosen for your new worktops.

Island end panels & waterfall ends

As you can see from the image of a slab to the right , an island unit and end panel are to be cut next to each other , both from the same slab, so the vein is continuous through the island and down into the end panel. This is also shown in the second image on the far right of how this would look when fitted (A.K.A a waterfall edge)

If another end panel was needed for the other side of the island, this would have to be cut from another slab so the vein would not run through or match up exactly. This problem also occurs when the island unit is too long so an end panel cannot be taken from the same slab.

Wall panels & full wall cladding

Another way to illustrate and highlight the issue is with wall panels, used to clad a wall. As you can see from the image to the left, this wall panel appears to be in one piece. Actually, this is split into 3 sections and jointed. There is a piece under each lower unit and a section in the middle that reaches up to the extractor unit. To make all the vein run together, this piece had to me made from one larger piece, and then split into the 3 sections.

The second example on the left shows a full-length wall splashback, made in 3 pieces, all cut from the same slab. Due to the full length of the wall being longer than the length of a full slab, the 3 pieces could not be cut from next to each other on the slab. The vein does not continue from one piece to the next. However, all 3 pieces were able to be cut from one single slab. You may also notice that the vein from the worktops to the wall splash-back is not continuous either. This is quite normal as its virtually impossible to match in every joint.

Often with a design like this, a joint would be necessary. It not an issue to manufacture the piece in one but it is sometimes problematic for the fitters to install it in one. Attempting to create a nice tight fit with little gaps, yet using larger pieces could damage walls, end panels or units.

Matching pattern Vs lower prices

Also, there are cost implications to consider. When creating a quote, we firstly look at how many slabs are needed for a project. We try to minimize the number of slabs by getting as many pieces as possible out of a slab, with very little waste.

Needing less material by utilizing as much of the slab as possible keeps initial quotes low. We would always do this unless the customer specifies otherwise.

However, in doing so the pieces that will be next to each other in the final kitchen layout, may not be from next to each other on the slab so the vein and pattern matching will not match through.