UNDERMOUNT SINKS

Under-mount sinks are the most popular type of sink with a granite, quartz or porcelain surface. As the sink is set under the worktop level, the edges of the worktop around the sink are visible, so a polished edge is required on the inside of the sink cut out.

Under-mounted sinks are available in a verity of materials such as stainless steel, all Resin,Granite and resin mix, Ceramic and quartz.

Usually seen in most kitchens with a set of 5 drainer grooves, this type of sink is either bonded to the bottom of the worktop or sits on batons attached to the sides of the unit to offer support. Heavier sinks such as ceramic or those made of quartz require extra support. various types of support can be added, such as a wooden shelf or specialist metal brackets.

Undermount sink – Granite & resin

The above image shows an undermounted sink made from a mixture of granite & resin. Most sink manufacturers make this type of sink in a verity of colours, shapes and sizes.

Undermounted sink – Stainless steel

The above image shows a 1.5 stainless steel sink . A popular option due to lower cost but is prone to scratches over time. Available in many sizes and configurations.

Ceramic undermounted sink

The above image shows an undermounted ceramic 1.5 sink . Most sink manufacturers make this type of sink in a verity of colours, shapes and sizes.

Metal support bars

If needed on heavier sinks , supporting metal framework and bars can be attached to the kitchen unit. These kits are adjustable to make the fitting process easier.

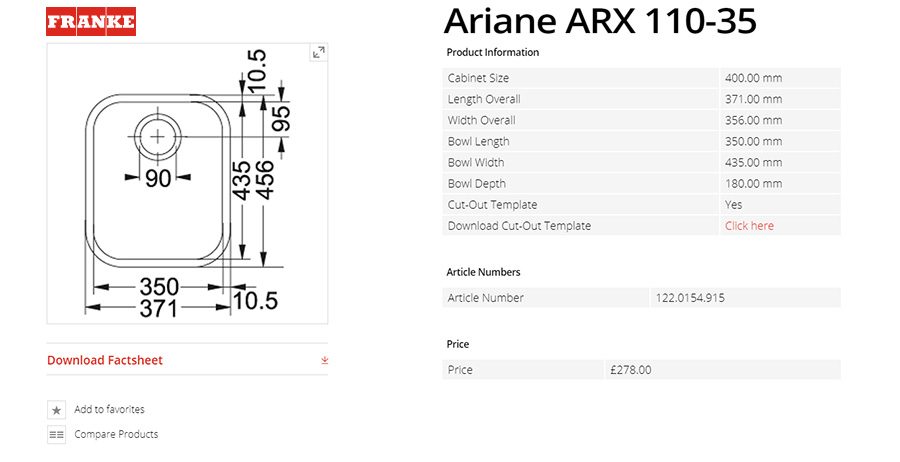

Sink type, make & model

The cut-out size for the specific sink you have chosen is a crucial piece of information as each sink can be different. If you obtain the exact make & model of your sink, either a dimensioned drawing or a .DXF file will be available from the manufacturer’s website. If possible, a .DXF file is best as this can be imported into our CNC machine to fabricate an exact, perfect cut out to suit your sink .

The first example shows the basic information supplied by the sink supplier. However, this does not show us the actual sizes needed for the cut out or sizes of the internal radius corners. This is why a .DXF file or a complete technical drawing is needed. Without all the relevant dimensions and radius sizes, there is no way to manufacture the exact cut out needed.

Here we see the same sink but with all the information needed for us to draw the sink on our CAD system for the CNC . Notice how on the first drawing the sink looks rectangular with 4 radius corners, where in reality the sides are actually slightly curved with a radius of 3999mm. There is also a mm or so difference in sizes with the two drawings, yet this is crucial to how the finished product will look , ensuring the cut out matches the sink, as the manufacturer intended.

Sink cut out size

Various options are available for the size of the sink cut out.

- Zero reveal -flush with the sink

- Positive reveal -Showing the sink

- Negative reveal -worktop over hangs the sink

We will manufacture the cut out to the dimensions and specification of the sink manufacturer. This could be any of the 3 options listed as each manufacturer and sink are different.

If you would like the cut out to be manufactured in a different way, you will need to discuss and confirm this with the fitter on site at the template stage.

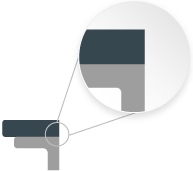

ZERO REVEAL

The worktops would be flush to the sink

POSITIVE REVEAL

Showing the rim of the sink

NEGATIVE REVEAL

Worktops overhanging the sink

To have any one of the options listed above isn’t a problem on most sinks and usually only a couple of mouse clicks on the CNC machine program. Provided we have had the correct information supplied by the customer on the sink manufacturers dimensions, we can alter the cut out to the customers wishes. If we do not have the correct information we will manufacture as we see fit but cannot take responsibility if after installation, its not what the customer wanted.

Choosing the correct size sink

Sink size & position

When choosing your sink its important to make sure it will fit within the unit. In the example to the right, there is a kitchen unit that’s 900mm wide to house the sink. Just remember that you will have to reduce these sizes by the thickness of the carcass (18mm approx.) x 2 to give you an internal unit sizes of approx. 864mm, if the drawing show a 750mm cabinet size.

In comparison, a standard 600 wide unit, usually allows 564mm on the inside to fit the sink in.

When the fitter arrives on site to make the template/ take sizes you will need to confirm the position of the sink within the unit. Sometimes, due to other constraints, the sink may need to be fitted off centre, to the left or right of the unit.

PLEASE NOTE : Make sure you don’t buy a sink that is too large , not only in width of the unit but in the depth from front to back of the worktops. Sinks that are too big cannot be fitted with a tap. We recommend 400mm max or ideally, 370mm